|

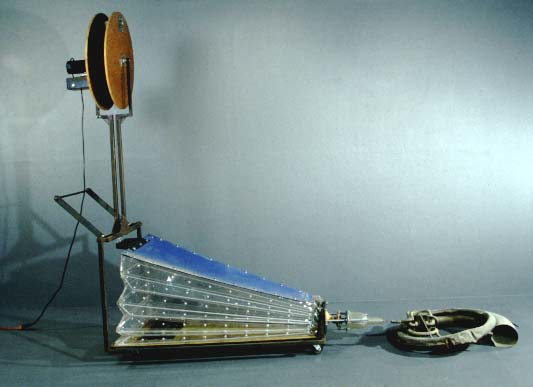

A mechanical bellows on wheels makes a soft sound for the old tuba. A motor is mounted on one side of the wooden wheel mechanism. A cable is attached to a rod connecting the two wooden wheels. The other end of the cable is attached to the wide end of the bellows. As the wooden wheels turn, the cable pulls the bellows up, the weight of the steel plate at the wide end of the bellows forces it back down. Holes in the bottom plate of the bellows allow air to enter the inner space as the bellows is pulled up. Rubber flaps over the holes prevent air from passing out as the bellows compress. |

|

The air is forced out through the narrower end of the bellows, through a latex diaphram, into a translucent hollow-cast plastic form and to a small reed from a pitch pipe. The cylindrical housing for the reed protrudes slightly from the cast plastic form. The tuba is positioned so that the small tube where the mouthpiece used to attach is about a half inch (roughly 1cm) from the reed. The vinyl and plexiglass sides of the bellows creak and the reed emits a soft sound as the bellows compress. |